Chida ndi chimodzi mwazinthu zofunika kwambiri pamakina opangira makina.Ndi chitukuko cha sayansi ndi zamakono, chida chasintha kuchokera ku chida choyambirira cha alloy kupita ku chida chogwiritsidwa ntchito kwambiri.Kupukuta ndi kuyikanso kwa simenti ya carbide ndi zida zachitsulo zothamanga kwambiri ndizofala pakalipano.Ngakhale mtengo wa zida zopukutiranso kapena kuyikanso ndi gawo laling'ono chabe la mtengo wopanga zida zatsopano, zitha kutalikitsa moyo wa chida ndikuchepetsa mtengo wopanga.Regrinding ndi njira yochizira ya zida zapadera kapena zida zodula.Zida zomwe zimatha kupangidwanso kapena kuzikutidwanso zimaphatikizapo zobowola, zodulira mphero, ma hobs ndi zida zopangira.

Chida regrilling

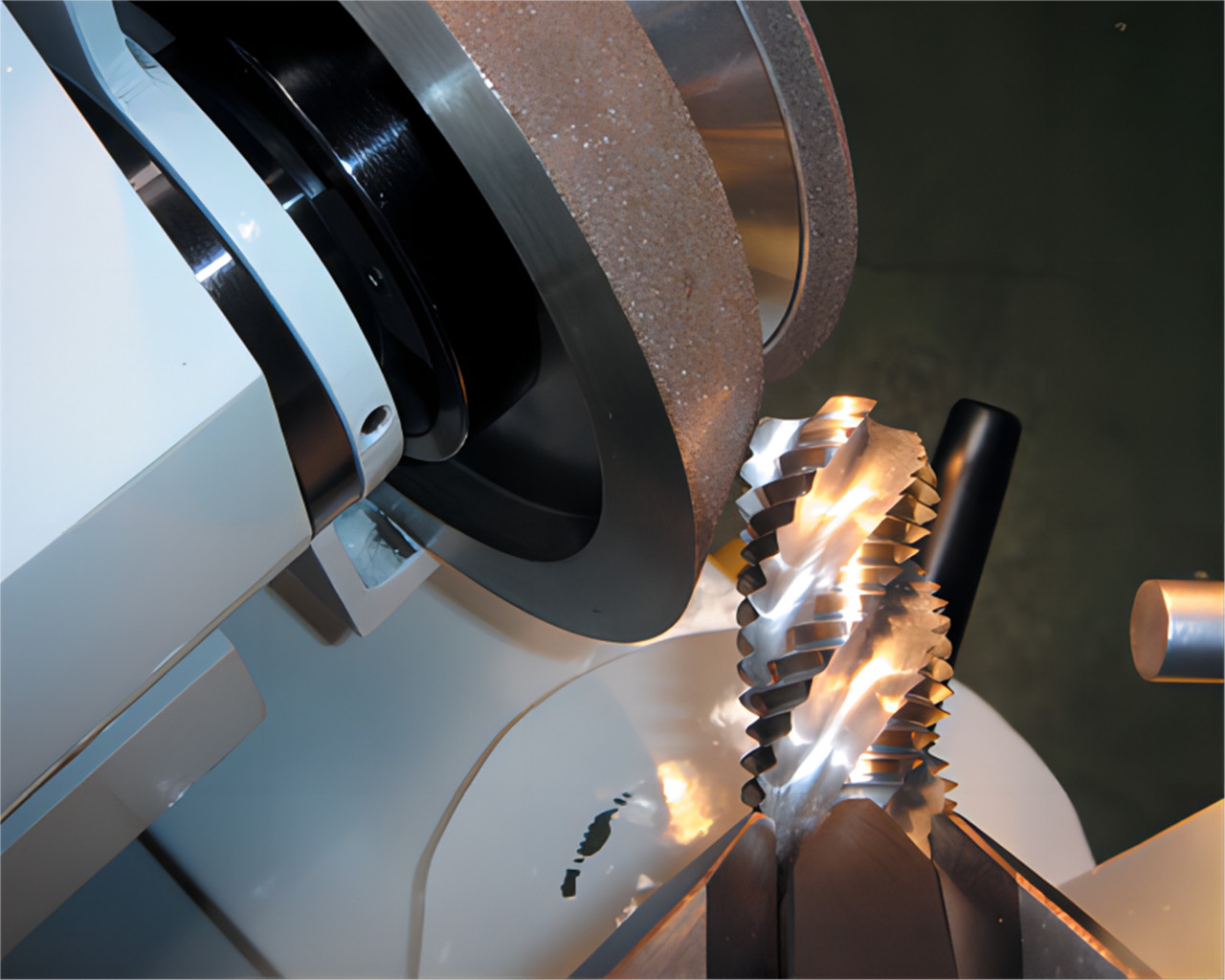

Mu regrinding ndondomeko kubowola kapena mphero wodula, m'pofunika pogaya m'mphepete kuchotsa ❖ kuyanika koyambirira, kotero gudumu lopera lomwe likugwiritsidwa ntchito liyenera kukhala ndi kuuma kokwanira.Kukonzekera koyambirira kwa m'mphepete mwa kudula ndikofunika kwambiri.Sikoyenera kuonetsetsa kuti mawonekedwe a geometric apachiyambi kudula m'mphepete akhoza kwathunthu ndi molondola anapitiriza pambuyo chida regrinding, komanso amafuna kuti PVD TACHIMATA chida ayenera "otetezeka" regrinding.Choncho, m'pofunika kupewa njira yowonongeka (monga kugaya movutikira kapena kupukuta kouma, kumene pamwamba pa chidacho chimawonongeka chifukwa cha kutentha kwakukulu).

Kuchotsa zokutira

Chidacho chisanapangidwenso, zokutira zonse zoyambirira zimatha kuchotsedwa ndi njira zama mankhwala.Njira yochotsera mankhwala nthawi zambiri imagwiritsidwa ntchito pazida zovuta (monga ma hobs ndi ma broaches), kapena zida zokhala ndi zokutira zingapo ndi zida zomwe zimakhala ndi zovuta zobwera chifukwa cha makulidwe a zokutira.Njira yochotsera kupaka mankhwala nthawi zambiri imakhala ndi zida zachitsulo zothamanga kwambiri, chifukwa njirayi idzawononga gawo lapansi la simenti ya carbide: njira yochotsera zokutira imasefa cobalt kuchokera ku gawo lapansi la simenti ya carbide, zomwe zimapangitsa kuti pakhale porosity yamadzi. gawo lapansi, mapangidwe a pores ndi zovuta kupakanso.

"Njira yochotseramo mankhwala imasankhidwa kuti ichotseretu dzimbiri za zokutira zolimba pazitsulo zothamanga kwambiri."Chifukwa matrix opangidwa ndi simenti ali ndi zinthu zomwe zimafanana ndi zomwe zili mu zokutira, zosungunulira zochotsa mankhwala zimatha kuwononga matrix opangidwa ndi simenti kuposa matrix othamanga kwambiri.

Kuphatikiza apo, pali njira zamakina zovomerezeka zoyenera kuchotsa zokutira za PVD.Munjira zamakina izi, pali kachitidwe kakang'ono kokha pakati pa njira yochotsera zokutira ndi matrix opangidwa ndi simenti ya carbide, koma njirazi sizinagwiritsidwe ntchito kwambiri pakadali pano.Kuonjezera apo, pali njira zina zoyeretsera zokutira, monga laser processing, abrasive blasting, etc. Njira yochotsera mankhwala ndiyo njira yodziwika bwino, chifukwa imatha kupereka kufanana kwabwino kwa kuchotsa pamwamba.

Pakalipano, njira yowonongeka ndikuchotsa chophimba choyambirira cha chida kudzera mu ndondomeko yobwezeretsanso.

Economy yokonzanso

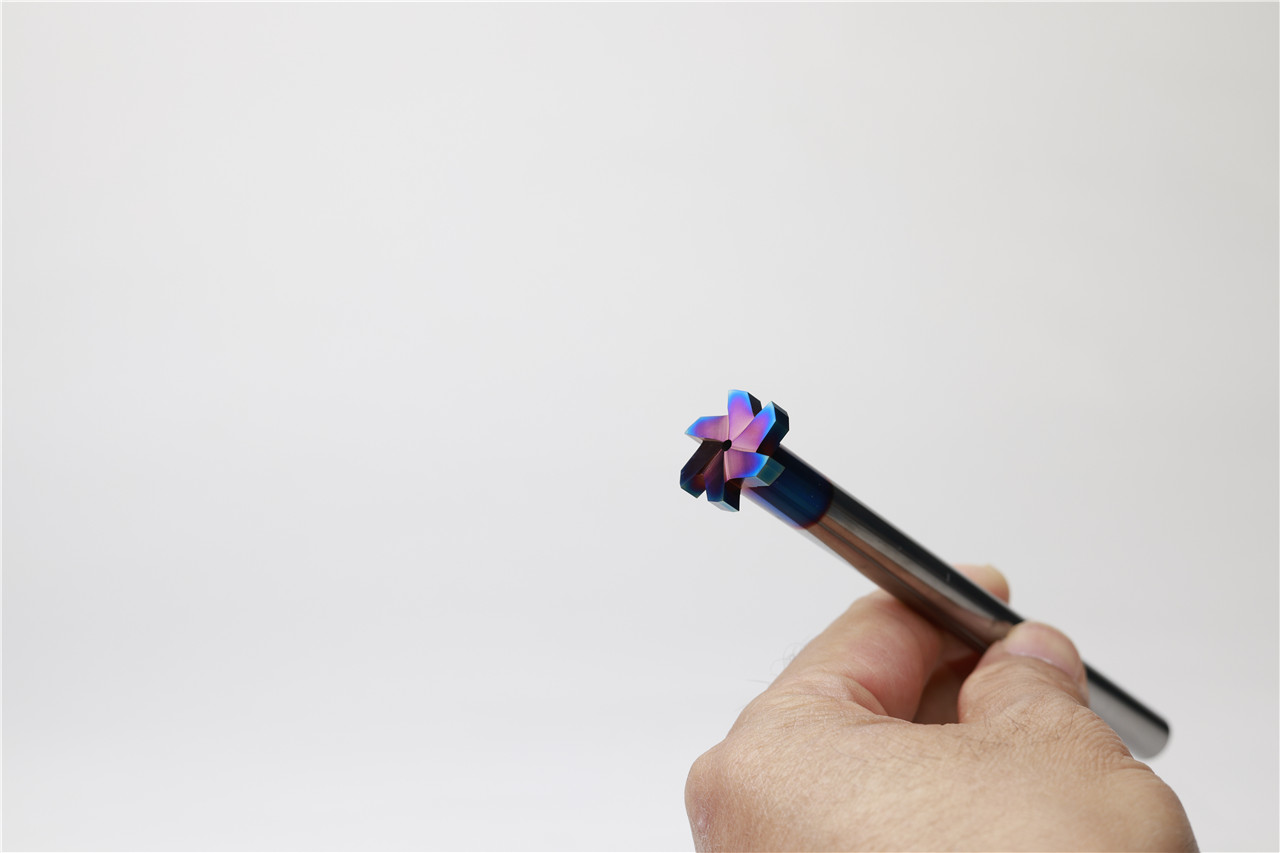

Zomwe zimagwiritsidwa ntchito kwambiri ndi TiN, TiC ndi TiAlN.Zovala zina zolimba kwambiri za nayitrogeni / carbide zagwiritsidwanso ntchito, koma sizofala kwambiri.Zida zokutira za diamondi za PVD zitha kupangidwanso ndikuzikutanso.Panthawi yobwezeretsanso, chidacho chiyenera "kutetezedwa" kuti zisawonongeke pamalo ovuta.

Izi nthawi zambiri zimakhala choncho: mutagula zida zopanda zokutira, ogwiritsa ntchito amatha kuziphimba zikafunika kupangidwanso, kapena kuyika zokutira zosiyanasiyana pazida zatsopano kapena zida zoyambira.

Kuchepetsa recoating

Monga momwe chida chimatha kubwezeretsedwanso nthawi zambiri, nsonga yodula ya chida imathanso kukutidwa nthawi zambiri.Chofunikira pakuwongolera magwiridwe antchito ndikupeza zokutira ndi zomatira bwino pamwamba pa chida chomwe chakhala chikuyambira.

Pokhapokha pokhapokha, zida zonsezo sizingasoweke kuti zikhale zophimbidwa kapena kuziyikanso panthawi iliyonse yopera, malingana ndi mtundu wa chida ndi magawo odulidwa omwe amagwiritsidwa ntchito popanga.Hobs ndi ma broaches ndi zida zomwe zimafunikira kuchotsa zokutira zonse zoyambirira pobwezeretsanso, apo ayi chidacho chidzachepetsedwa.Vuto lomatira lisanayambe kudziwika, chidacho chikhoza kubwezeretsedwanso kangapo popanda kuchotsa zokutira zakale.Ngakhale zokutira za PVD zimakhala ndi kupsinjika kotsalira kopindulitsa pa kudula zitsulo, kupanikizika kumeneku kumawonjezeka ndi kuchuluka kwa makulidwe a zokutira, ndipo zokutira zimayamba kutsika pambuyo podutsa malire okhazikika.Mukabwezeretsanso popanda kuchotsa chophimba chakale, makulidwe amawonjezeredwa kumtunda wakunja wa chidacho.Kwa kubowola, kumatanthauza kuti dzenje lalikulu likukula.Choncho, m'pofunika kuganizira chikoka cha makulidwe zina ❖ kuyanika pa m'mimba mwake kunja kwa chida, komanso chikoka cha awiri pa dimensional kulolerana wa machined dzenje awiri.

Kubowola kumatha kukutidwa ka 5 mpaka 10 osachotsa zokutira zakale, koma pambuyo pake, kumakumana ndi zovuta zazikulu.Dennis Klein, wachiwiri kwa purezidenti wa Spec Tools, amakhulupirira kuti makulidwe a zokutira sizingakhale vuto mkati mwazolakwika za ± 1 µ m;Komabe, pamene cholakwikacho chili mkati mwa 0.5 ~ 0.1 µ m, chikoka cha makulidwe a zokutira chiyenera kuganiziridwa.Malingana ngati makulidwe ophimbawo sakhala vuto, zida zokongoletsedwa ndi reground zitha kukhala ndi ntchito yabwino kuposa zoyambirira.

Nthawi yotumiza: Feb-24-2023