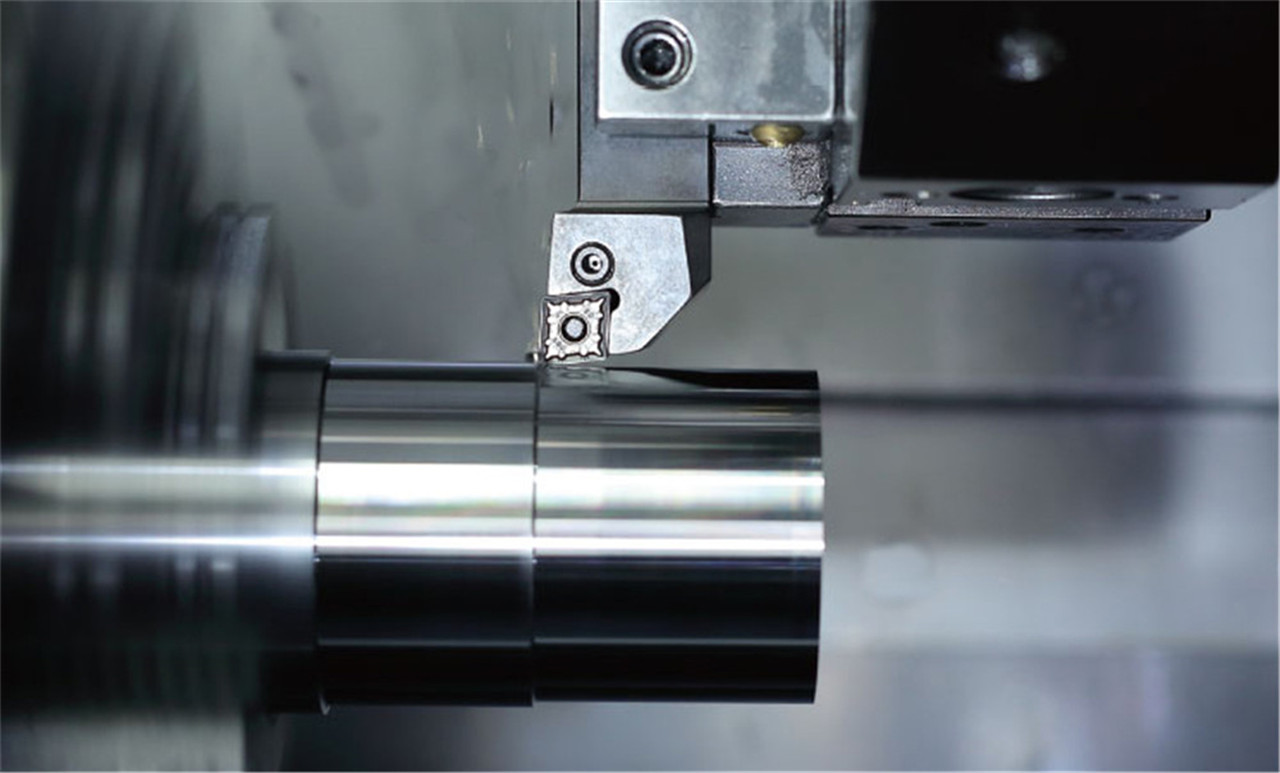

Ndi chitukuko cha sayansi ndi zamakono zamakono, zipangizo zaumisiri zochulukira ndi kuuma kwakukulu zimagwiritsidwa ntchito, pamene teknoloji yotembenuzidwa yachikhalidwe sichikhoza kapena sichikhoza kukwaniritsa kukonzanso zipangizo zina zolimba kwambiri.Carbide yokutidwa, zoumba, PCBN ndi zida zina zapamwamba kwambiri kutentha kuuma, kukana kuvala ndi kukhazikika thermochemical, amene amapereka zofunika kwambiri podula zipangizo mkulu kuuma, ndipo apindula kwambiri pakupanga.Zomwe zimagwiritsidwa ntchito ndi chida cholimba kwambiri komanso kapangidwe kake ka zida ndi magawo a geometric ndizomwe zimafunikira kuzindikira kutembenuka kolimba.Chifukwa chake, momwe mungasankhire zida zolimba kwambiri ndikupanga chida choyenera komanso magawo a geometric ndikofunikira kuti mukwaniritse kutembenuka kolimba!

(1) Carbide wokutidwa ndi simenti

Ikani gawo limodzi kapena zingapo za TiN, TiCN, TiAlN ndi Al3O2 zokhala ndi kukana kwabwino pazida zokhala ndi simenti ya carbide zolimba bwino, ndipo makulidwe ake ndi 2-18 μ m.The ❖ kuyanika kawirikawiri amakhala otsika kwambiri matenthedwe madutsidwe kuposa chida gawo lapansi ndi workpiece zakuthupi, amene amafooketsa matenthedwe zotsatira za gawo lapansi chida;Kumbali inayi, imatha kupititsa patsogolo kukangana ndi kumamatira pakudula ndikuchepetsa kutulutsa kutentha.

Ngakhale zokutira za PVD zikuwonetsa zabwino zambiri, zokutira zina monga Al2O3 ndi diamondi zimakonda kutengera ukadaulo wokutira wa CVD.Al2O3 ndi mtundu wa ❖ kuyanika ndi kukana kutentha kwamphamvu ndi kukana makutidwe ndi okosijeni, amene akhoza kulekanitsa kutentha kwaiye kwa kudula ku chida enieni.Ukadaulo wokutira wa CVD ungaphatikizirenso ubwino wa zokutira zosiyanasiyana kuti mukwaniritse zodula bwino ndikukwaniritsa zosowa za kudula.

Poyerekeza ndi zida za simenti za carbide, zida zokutira za carbide zakhala zikuyenda bwino kwambiri pakulimba, kulimba komanso kukana kuvala.Mukatembenuza chogwirira ntchito ndi kuuma kwa HRC45 ~ 55, carbide yokhala ndi simenti yotsika mtengo imatha kuzindikira kutembenuka kothamanga kwambiri.M'zaka zaposachedwa, opanga ena apititsa patsogolo magwiridwe antchito a zida zokutira powonjezera zida zokutira ndi njira zina.Mwachitsanzo, opanga ena ku United States ndi Japan amagwiritsa ntchito zokutira za Swiss AlTiN ndi ukadaulo watsopano wopaka utoto kuti apange masamba okutidwa molimba kwambiri monga HV4500 ~ 4900, omwe amatha kudula chitsulo cha HRC47 ~ 58 pa liwiro la 498.56m/min. .Pamene kutentha kutembenuka kufika 1500 ~ 1600 ° C, kuuma sikumachepabe ndipo sikumawonjezera oxidize.Moyo wautumiki wa tsambalo ndi kanayi kuposa wa tsamba lokutidwa, pomwe mtengo wake ndi 30% yokha, ndipo zomatira ndizabwino.

(2) Ceramicmaterial

Ndikusintha kosalekeza kwa kapangidwe kake, kapangidwe kake ndi kanikidwe kake, makamaka chitukuko cha nanotechnology, zida za ceramic zidapangitsa kuti zikhale zotheka kulimbitsa zida za ceramic.Posachedwapa, zoumba zadothi zingayambitse kusintha kwachitatu pakudula pambuyo pa chitsulo chothamanga kwambiri ndi carbide yolimba.Zida za ceramic zili ndi ubwino wa kuuma kwakukulu (HRA91 ~ 95), kulimba kwakukulu (kupinda mphamvu 750 ~ 1000MPa), kukana kuvala bwino, kukhazikika kwa mankhwala, kukana kwabwino kwa adhesion, coefficient yotsika ndi mtengo wotsika.Osati zokhazo, zida za ceramic zilinso ndi kuuma kwa kutentha kwakukulu, komwe kumafika HRA80 pa 1200 ° C.

Panthawi yodula bwino, chida cha ceramic chimakhala cholimba kwambiri, ndipo liwiro lake lodulira limatha kukhala nthawi 2 ~ 5 kuposa la carbide yomangidwa.Ndikoyenera makamaka kupangira zida zolimba kwambiri, zomaliza komanso zothamanga kwambiri.Itha kudula zitsulo zolimba zosiyanasiyana komanso zitsulo zolimba zolimba zolimba mpaka HRC65.Zomwe zimagwiritsidwa ntchito nthawi zambiri ndi zitsulo za alumina zochokera ku ceramic, silicon nitride based ceramics, cermets ndi whisker tougher ceramics.

Zida za ceramic zochokera ku alumina zimakhala ndi kuuma kofiira kwambiri kuposa carbide yomangidwa.Nthawi zambiri, m'mphepete mwake sipanga pulasitiki kupindika pansi pamikhalidwe yodula kwambiri, koma mphamvu zake ndi kulimba kwake ndizochepa kwambiri.Pofuna kukonza kulimba kwake komanso kukana kwake, kusakaniza kwa ZrO kapena TiC ndi TiN kumatha kuwonjezeredwa.Njira ina ndikuwonjezera ndevu zachitsulo kapena silicon carbide.Kuphatikiza pa kuuma kofiira kwambiri, zoumba za silicon nitride zochokera kumakhalanso ndi kulimba kwabwino.Poyerekeza ndi zitsulo zopangidwa ndi aluminiyamu, kuipa kwake ndikuti ndikosavuta kutulutsa kutentha kwambiri popanga zitsulo, zomwe zimakulitsa kuvala kwa zida.Zoumba za silicon nitride zochokera ku ceramic zimagwiritsidwa ntchito makamaka potembenuza pang'onopang'ono ndi mphero yachitsulo chotuwa.

Cermet ndi mtundu wa zinthu zopangidwa ndi carbide, momwe TiC ndi gawo lalikulu lolimba (0.5-2 μm) Amaphatikizidwa ndi zomangira za Co kapena Ti ndipo ndizofanana ndi zida zomangira simenti, koma zimakhala ndi mgwirizano wochepa, mikangano yabwino komanso yabwino. kuvala kukana.Imatha kupirira kutentha kwambiri kuposa carbide wamba, koma ilibe kukana kwa simenti ya carbide, kulimba panthawi yodula kwambiri komanso mphamvu pa liwiro lotsika komanso chakudya chachikulu.

(3) Kiyubiki boron nitride (CBN)

CBN ndi yachiwiri kwa diamondi pakuuma komanso kukana kuvala, ndipo imakhala ndi kuuma kwa kutentha kwambiri.Poyerekeza ndi zitsulo za ceramic, kukana kwake kutentha ndi kukhazikika kwa mankhwala ndizosauka pang'ono, koma mphamvu yake ndi ntchito yotsutsa-kuphwanya ndi yabwino.Imagwiritsidwa ntchito kwambiri pakudula chitsulo cholimba (HRC ≥ 50), chitsulo cha pearlitic gray cast, chilled cast iron and superalloy.Poyerekeza ndi zida za simenti za carbide, liwiro lake lodulira limatha kuonjezedwa ndi dongosolo limodzi la ukulu.

Chida chophatikizika cha polycrystalline kiyubic boron nitride (PCBN) chokhala ndi CBN yayikulu chimakhala ndi kuuma kwambiri, kukana kuvala bwino, kulimba mtima kwakukulu komanso kulimba kwamphamvu.Zoyipa zake ndi kusakhazikika kwamafuta komanso kutsika kwamphamvu kwamankhwala.Ndiwoyenera kudula ma alloys osagwira kutentha, chitsulo choponyedwa ndi zitsulo zopangidwa ndi chitsulo.Zomwe zili mu CBN particles mu zida za PCBN ndizochepa, ndipo kuuma kwa zida za PCBN zogwiritsira ntchito zoumba ngati binder ndizochepa, koma zimapanga kusakhazikika kwamafuta komanso kutsika kwamankhwala azinthu zakale, ndipo ndi koyenera kudula zitsulo zolimba.

Mukadula chitsulo chotuwa ndi chitsulo cholimba, chida cha ceramic kapena chida cha CBN chingasankhidwe.Pachifukwa ichi, mtengo wa phindu ndi kusanthula khalidwe la processing ziyenera kuchitidwa kuti mudziwe yemwe angasankhe.Kuuma kukakhala kocheperako kuposa HRC60 ndikulandila chakudya chochepa, chida cha ceramic ndichosankha bwino.Zida za PCBN ndizoyenera kudula ma workpieces ndi kuuma kwakukulu kuposa HRC60, makamaka kwa makina odzipangira okha komanso makina olondola kwambiri.Kuphatikiza apo, kupsinjika kotsalira pa workpiece pambuyo kudula ndi chida cha PCBN ndikokhazikikanso kuposa komwe kumakhala ndi chida cha ceramic pansi pakuvala komweko.

Mukamagwiritsa ntchito chida cha PCBN kuti muwumitse chitsulo cholimba, mfundo zotsatirazi ziyeneranso kutsatiridwa: sankhani kuya kwakukulu komwe kungathekere pansi pa chikhalidwe chomwe chimapangitsa kuti chiwongolero cha makina chitheke, kuti kutentha komwe kumapangidwa m'dera lodulirako kuchepetse. zitsulo kutsogolo kwa m'mphepete kwanuko, zomwe zingathe kuchepetsa kuvala kwa chida cha PCBN.Kuonjezera apo, pogwiritsa ntchito kuya kwazing'ono, ziyenera kuganiziridwanso kuti kusauka kwa matenthedwe a chipangizo cha PCBN kungapangitse kutentha m'dera locheka mochedwa kwambiri kuti zisawonongeke, komanso kumeta ubweya wa ubweya kungathenso kutulutsa zitsulo zomveka bwino, kuchepetsa kuvala zodula.

2. Mapangidwe a tsamba ndi magawo a geometric a zida zolimba kwambiri

Kutsimikiza koyenera kwa mawonekedwe ndi magawo a geometric a chida ndikofunikira kwambiri kuti apereke kusewera kwathunthu pakudula kwa chida.Pankhani ya mphamvu chida, chida nsonga mphamvu ya akalumikidzidwa tsamba zosiyanasiyana kuchokera pamwamba mpaka pansi ndi: kuzungulira, 100 ° diamondi, lalikulu, 80 ° diamondi, makona atatu, 55 ° diamondi, 35 ° diamondi.Pambuyo pa kusankhidwa kwa tsamba, mawonekedwe a tsamba ndi mphamvu zapamwamba adzasankhidwa.Zokhotakhota zolimba ziyeneranso kusankhidwa zazikulu momwe zingathere, ndipo makina okhwima ayenera kuchitidwa ndi masamba ozungulira komanso akulu arc radius.Kumapeto kwa arc radius ndi pafupifupi 0.8 pomaliza μ Pafupifupi m.

Zitsulo zachitsulo zolimba zimakhala zofiira ndi zofewa, zokhala ndi zowonongeka kwambiri, zosavuta kuthyoka komanso zosamangirira.Chitsulo cholimba chachitsulo chimakhala chapamwamba kwambiri ndipo nthawi zambiri sichimapanga kusonkhanitsa kwa chip, koma mphamvu yodulira ndi yayikulu, makamaka mphamvu yodulira ma radial ndi yayikulu kuposa mphamvu yayikulu yodulira.Choncho, chidacho chiyenera kugwiritsa ntchito mbali yolakwika ya kutsogolo (pita ≥ - 5 °) ndi kumbuyo kwakukulu (ao = 10 ° ~ 15 °).Waukulu kupatuka ngodya zimadalira rigidity wa makina chida, zambiri 45 ° ~ 60 °, kuchepetsa macheza workpiece ndi chida.

Nthawi yotumiza: Feb-24-2023