1.Kudula zida zakuthupi

Zida wamba zida pogaya zida monga: mkulu-liwiro zitsulo, ufa zitsulo mkulu-liwiro zitsulo, simenti carbide, PCD, CBN, cermet ndi zipangizo superhard.Zida zachitsulo zothamanga kwambiri ndi zakuthwa komanso zimakhala zolimba bwino, pomwe zida za carbide zimakhala zolimba koma zolimba.Kuchulukana kwa zida za simenti za carbide ndizokwera kwambiri kuposa zida zachitsulo zothamanga kwambiri.Zida ziwirizi ndizomwe zimagwiritsidwa ntchito pobowola, ma reamers, odulira mphero ndi matepi.Ntchito ya ufa zitsulo mkulu liwiro zitsulo ndi pakati pa zipangizo ziwiri pamwamba, ndipo zimagwiritsa ntchito kupanga akhakula mphero wodula ndi wapampopi.

Zida zachitsulo zothamanga kwambiri sizimakhudzidwa ndi kugunda chifukwa cha kulimba kwawo bwino.Komabe, zida za carbide zokhala ndi simenti zimakhala ndi kuuma kwambiri komanso kuphulika, zimakhudzidwa kwambiri ndi kugunda, ndipo m'mphepete ndi kosavuta kulumpha.Choncho, pogaya, m'pofunika kusamala kwambiri za ntchito ndi kuyika kwa simenti zida carbide kupewa kugunda pakati pa zida kapena kugwa kwa zida.

Chifukwa chakuti kulondola kwa zida zazitsulo zothamanga kwambiri ndizochepa, zofunikira zawo zogaya sizokwera, ndipo mitengo yake siili yokwera, opanga ambiri amapanga zida zawo zopangira zida kuti azipera.Komabe, zida za simenti za carbide nthawi zambiri zimafunika kutumizidwa ku malo opera akatswiri kuti apeye.Malinga ndi ziwerengero za malo ambiri opangira zida, zoposa 80% ya zida zomwe zimatumizidwa kuti zikonze ndi zida za simenti za carbide.

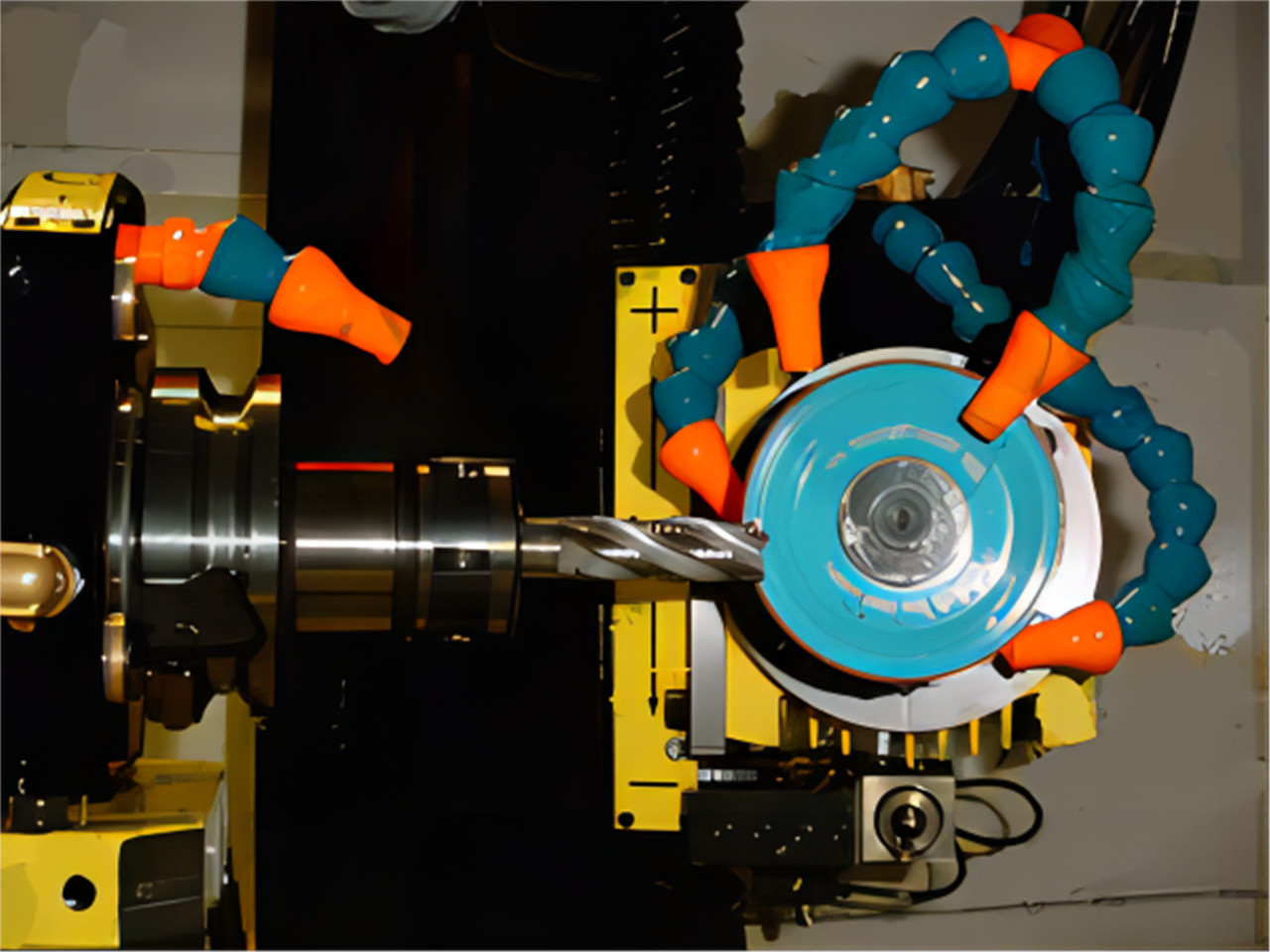

2. Kudula Chida chopukusira

Chifukwa zida zachitsulo ndizovuta kwambiri, zimatha kusinthidwa ndikupera.Zopukusira zida zomwe zimagwiritsidwa ntchito popanga zida ndikupera ndi izi:

(1).Makina opangira grooving: kugaya poyambira kapena kumbuyo kwa zibowola, mphero ndi zida zina.

(2).Chopukusira: Kupera ngodya ya conical pamwamba (kapena eccentric back angle) ya pobowola.

(3) Makina odulira: Konzani m'mphepete mwabowo.

(4).Buku ponseponse chida chopukusira: akupera bwalo akunja, poyambira, kumbuyo, pamwamba ngodya, yopingasa m'mphepete, ndege, kutsogolo kwa nkhope, etc. Nthawi zambiri amagwiritsidwa ntchito zipangizo ndi zochepa zochepa ndi mawonekedwe ovuta.

(5).CNC akupera makina: zambiri kugwirizana asanu olamulira, ndi ntchito anatsimikiza ndi mapulogalamu.Nthawi zambiri amagwiritsidwa ntchito popera zida zokhala ndi kuchuluka kwakukulu komanso zofunikira zolondola kwambiri, koma osati zovuta, monga zobowola, mphero, zopukutira, ndi zina zambiri. Ogulitsa zazikulu zopukutira zotere akuchokera ku Germany, Switzerland, United States, Australia ndi Japan. .

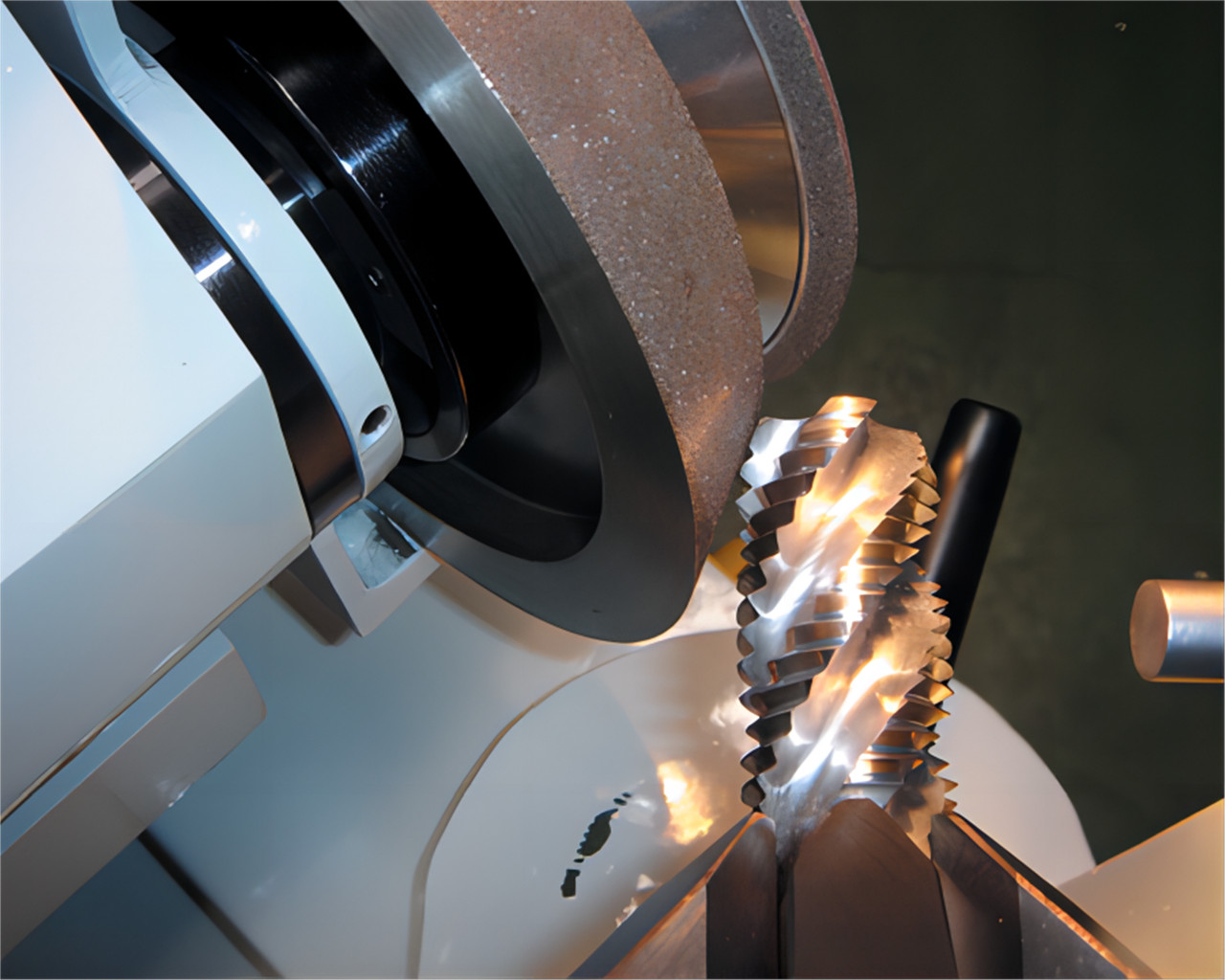

3.gudumu lopera

(1).Abrasive particles

Magudumu abrasive abrasive particles a zipangizo zosiyanasiyana ndi oyenera pogaya zipangizo zosiyanasiyana.Magawo osiyanasiyana a chida amafunikira makulidwe osiyanasiyana abrasive kuti atsimikizire kuphatikiza kwabwino kwa chitetezo cham'mphepete ndi kukonza bwino.

Alumina: amagwiritsidwa ntchito popera zida za HSS.Gudumu lopera ndilotsika mtengo komanso losavuta kusinthidwa kukhala mawonekedwe osiyanasiyana pogaya zida zovuta (corundum).

Silicon carbide: amagwiritsidwa ntchito kukonza gudumu lopera la CBN ndi gudumu lopera la diamondi.

CBN (cubic boron carbide): amagwiritsidwa ntchito popera zida za HSS.Mtengo wapamwamba, koma wokhazikika.

Padziko lonse lapansi, gudumu lopera limaimiridwa ndi B, monga B107, pomwe 107 imayimira kukula kwa tinthu tating'onoting'ono.

Daimondi: Amagwiritsidwa ntchito popera zida za HM.Ndi okwera mtengo koma cholimba.

(2).Maonekedwe

Kuti athandizire kugaya mbali zosiyanasiyana za chida, gudumu lopera liyenera kukhala ndi mawonekedwe osiyanasiyana.Zomwe zimagwiritsidwa ntchito kwambiri ndi:

Parallel akupera gudumu (1A1): akupera pamwamba ngodya, awiri akunja, kumbuyo, etc.

Dished akupera gudumu (12V9, 11V9): akupera ozungulira poyambira, waukulu ndi wothandiza kudula m'mphepete mwa mphero wodula, yokonza m'mphepete yopingasa, etc.

Pambuyo pa gudumu lopera lagwiritsidwa ntchito kwa nthawi, mawonekedwe ake (kuphatikizapo ndege, ngodya ndi fillet R) ayenera kukonzedwa.Gudumu lopera liyenera kugwiritsa ntchito mwala woyeretsera kuti achotse tchipisi todzaza pakati pa njere za abrasive kuti gudumu logulira lizitha kugaya bwino.

4.Akupera muyezo

Kaya pali zida zabwino zopangira zida ndiye muyezo woyezera ngati malo ogawira ndi akatswiri.Mu muyezo akupera, magawo luso la kudula m'mphepete mwa zida zosiyanasiyana podula zipangizo zosiyanasiyana zambiri amatchulidwa, kuphatikizapo ngodya yokhotakhota, ngodya pamwamba, ngodya kutsogolo, ngodya kumbuyo, chamfer, chamfer ndi magawo ena (pa simenti carbide bit). , njira yodutsa m'mphepete mwake imatchedwa "chamfer", ndipo m'lifupi mwake chamfer imagwirizana ndi zinthu zomwe ziyenera kudulidwa, nthawi zambiri pakati pa 0.03-0.5Mm ndi 0.25Mm. imatchedwa "chamfer." Kampani iliyonse yaukatswiri imakhala ndi miyeso yakeyake yomwe yafotokozedwa mwachidule m'zaka zapitazi.

Kusiyana pakati pa HM bit ndi HSS bit:

HSS bit: ngodya yapamwamba nthawi zambiri imakhala madigiri 118, nthawi zina kuposa madigiri 130;Tsamba ndi lakuthwa;Zofunikira pakulondola (kusiyana kwa kutalika kwa tsamba, symmetry, circumferential runout) ndizochepa.Pali njira zambiri zokonzera tsamba lopingasa.

HM pang'ono: ngodya yapamwamba nthawi zambiri imakhala madigiri 140;Kubowolera molunjika nthawi zambiri kumakhala madigiri 130, ndipo zobowolera m'mbali zitatu nthawi zambiri zimakhala madigiri 150.Tsamba ndi nsonga (pamphepete) sizikhala zakuthwa ndipo nthawi zambiri zimadutsa, kapena zimatchedwa chamfer ndi chamfer;Zimafunika kulondola kwambiri.Tsamba lopingasa nthawi zambiri limadulidwa kukhala S-mawonekedwe kuti athandizire kusweka kwa chip.

Mbali yakumbuyo: Kumbuyo kwa tsamba ndikofunikira kwambiri pa chida.Ngodya yakumbuyo ndi yayikulu kwambiri, ndipo tsambalo ndi losavuta kulumpha ndi "kubaya";Ngati mbali yakumbuyo ndi yaying'ono kwambiri, kukangana kudzakhala kwakukulu kwambiri ndipo kudula kudzakhala kosayenera.

Mbali yakumbuyo ya chidacho imasiyanasiyana ndi zinthu zomwe ziyenera kudulidwa komanso mtundu ndi m'mimba mwake mwa chidacho.Nthawi zambiri, mbali yakumbuyo imachepa ndi kuchuluka kwa diameter ya chida.Kuonjezera apo, ngati zinthu zomwe ziyenera kudulidwa zimakhala zovuta, mbali yakumbuyo idzakhala yaying'ono, mwinamwake, mbali yakumbuyo idzakhala yaikulu.

5.Kudula Zida zowunikira zida

Zida zodziwira zida zodulira nthawi zambiri zimagawidwa m'magulu atatu: chida chokhazikitsira zida, projekiti ndi chida chapadziko lonse lapansi choyezera.Chida chokhazikitsa chida chimagwiritsidwa ntchito kwambiri pokonzekera zida (monga kutalika) kwa zida za CNC monga malo opangira makina, komanso pozindikira magawo monga ngodya, radius, kutalika kwa masitepe, ndi zina zambiri;Ntchito ya pulojekitiyi imagwiritsidwanso ntchito pozindikira magawo monga ngodya, radius, kutalika kwa sitepe, ndi zina zotero.Chida chapadziko lonse lapansi choyezera chida chimatha kuyeza magawo ambiri a geometric a chidacho, kuphatikiza mbali yakumbuyo.

Choncho, akatswiri chida akupera pakati ayenera okonzeka ndi chilengedwe chida kuyeza chida.Komabe, ndi ochepa ogulitsa zida zotere, ndipo pali zinthu zaku Germany ndi French pamsika.

6.Katswiri wogaya

Zida zabwino kwambiri zimafunikiranso anthu ogwira ntchito kuti azigwira ntchito, ndipo kuphunzitsa akatswiri opera ndi chimodzi mwamaulalo ofunikira kwambiri.Chifukwa cha makampani opanga zida omwe abwerera m'mbuyo ku China komanso kuchepa kwakukulu kwa maphunziro aukadaulo ndiukadaulo, maphunziro a akatswiri okupera zida amatha kuthetsedwa ndi bizinesi yokha.

7. Mapeto

Ndi zida zogaya, zida zoyesera ndi zida zina komanso miyezo yogaya, akatswiri opera ndi mapulogalamu ena, kugaya kwa zida zolondola kumatha kuyamba.Chifukwa cha zovuta zogwiritsira ntchito zida, malo ogaya akatswiri ayenera kusintha nthawi yake ndondomeko yopera molingana ndi kulephera kwa chida chophwanyidwa, ndikutsata momwe chidacho chikugwiritsidwira ntchito.Katswiri wogawira zida amayenera kufotokozera mwachidule zomwe akukumana nazo kuti agwiritse ntchito bwino komanso mwaukadaulo!

Nthawi yotumiza: Feb-24-2023